Should You Use a Vertical or Horizonal Masterbatch Mixer?

2024-06-12 Page view:

With the rapid development of the plastics and rubber industry, the application of resin mixing has become increasingly more important for plastic processors. An industrial mixer blends plastic resins uniformly to achieve the desired color combination. This ensures consistency and quality in the final product, making it essential for applications where precise color matching is crucial.

Vertical vs. Horizonal Masterbatch Mixer

There are a few methods to mix plastic pellets, each offering distinct advantages depending on the specific requirements of the production process. For example, the Wensui WSQF Vertical Mixer and WSQA Horizontal Masterbatch Mixer have unique differences in design and features, each offering distinct advantages and characteristics.

WSQF Vertical Mixer

The main advantages and features of the WSQF Vertical Mixer, including:

- Efficient Mixing: A spiral circulation mixing design enables more uniform and rapid mixing of raw materials, suitable for all kinds of plastic materials and masterbatch.

- Durable Materials: Barrels and mixing screw are made of stainless steel, both of which are rust free and easy to clean. The lower bearing design keeps the material from being contaminated and extends the bearing's lifespan.

- Safe Operation: Equipped with electric control safety protection devices to ensure operational safety and reduce usage risks.

- Highly Customizable: Tailored to meet customer needs, such as choosing a special version with heating function to cater to different application scenarios.

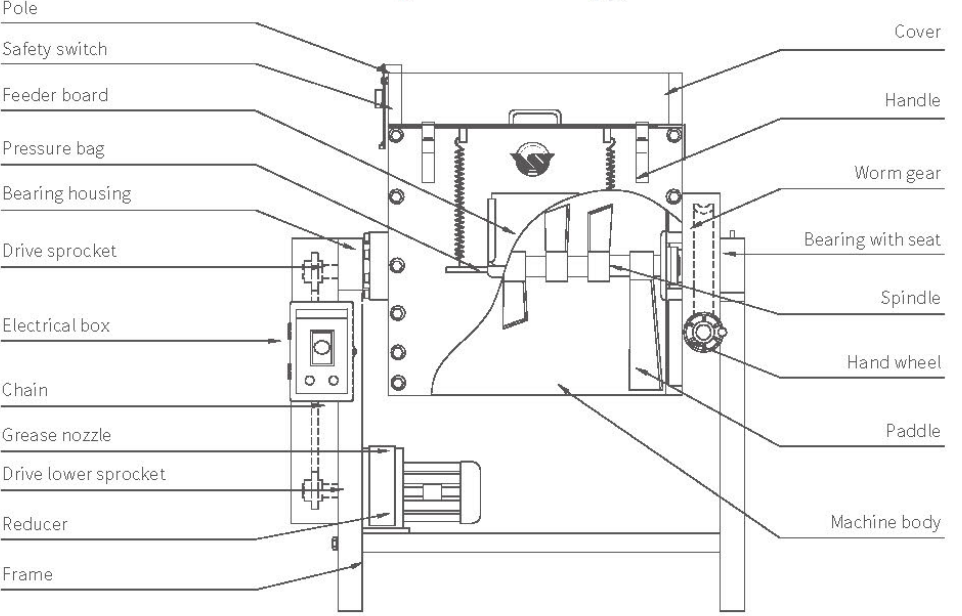

WSQA Horizontal Masterbatch Mixer

The WSQA Horizontal Masterbatch Mixer also has its unique characteristics, including:

- Large Capacity: The horizontal stirring shaft design allows the material to flow naturally during the mixing process, creating a circular or semi-circular mixing space, making it suitable for continuous operation on large-scale production lines.

- Precise Material Control: Due to its horizontal design, the WSQA series can effectively control the flow of materials, ensuring that the mixing effect of each batch meets the desired standards.

- Ease of Cleaning: The hopper can be tilted 100 degrees, facilitating unloading and cleaning, significantly reducing the workload and time required for cleaning during the production process.

- Flexible Timing Control: Timer able to set within 0-30 minutes.

Industrial Mixer Supplier

The Wensui WSQF Vertical Mixer and WSQA Horizontal Masterbatch Mixer have their respective applicable scenarios and advantages, capable of meeting the needs of specific applications. Do you know which mixer is more suitable for your production? Reach out to us and we will provide the right industrial mixer for your plastic processing production.

-

2024-10

-

2024-09

-

2024-09