Plastic Resin Linear Vibrating Screen

2024-10-18 Page view:

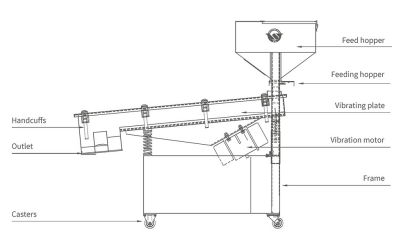

The linear vibrating screen is a precise screening device designed to handle large quantities of materials efficiently. Through vibration, the machine screens and filters out contaminants from plastic resin materials, ensuring that different production process requirements are met.

What is a Linear Vibrating Screen?

The linear vibrating screen operates by utilizing a motor to generate a excitation force, driving the screen body to vibrate. When materials are fed onto the screen surface, the vibration causes particles smaller than the mesh holes to pass through. Meanwhile, larger particles move forward along the screen surface and are discharged from the end as the oversize material. This process enables the efficient screening and grading of materials according to size.

Advantages of linear vibrating screen for plastics processing

1. High screening accuracy

In the plastics industry, there are different requirements for the particle size of raw material and recycled material. The mesh screen helps to separate plastic pellets from any unwanted material. The linear vibrating screen ensures that plastic particles are evenly distributed and move uniformly across the screen surface. This helps to accurately screen out plastic pellets that meet specific size requirements.

2. Efficient screening

Efficient screening with a mesh screen ensures precise separation of materials based on size, allowing only particles smaller than the mesh openings to pass through. This method enhances productivity by maintaining a consistent flow of materials and reducing the need for reprocessing.

3. Flexible structural design

The machine is portable with castor wheels. It is also light-weight and easy to move around your plastic product manufacturing factory.

Applications

1. Plastic pellets

For plastic resin pellets, the materials that do not meet the particle standard size are screened out to ensure product quality uniformity.

2. Recycled material

In the plastics recycling industry, recycled plastic material is often a mixture of materials in various shapes and sizes. Linear vibrating screens can pre-treat these recycled plastics by separating regrinds that are too large in size for further processing.

As a leader in the plastics and rubber industry, we have been specializing in the manufacturing of plastics processing equipment for over 35 years. We offer six main product series, including plastic shredders and crushers, dehumidifiers, dryers, mixers, vacuum autoloaders, water chillers, and robotic arms. Feel free to contact us and get a free quote.

-

2024-09